Durable & Strong Knitting Net Made from HDPE Fibers

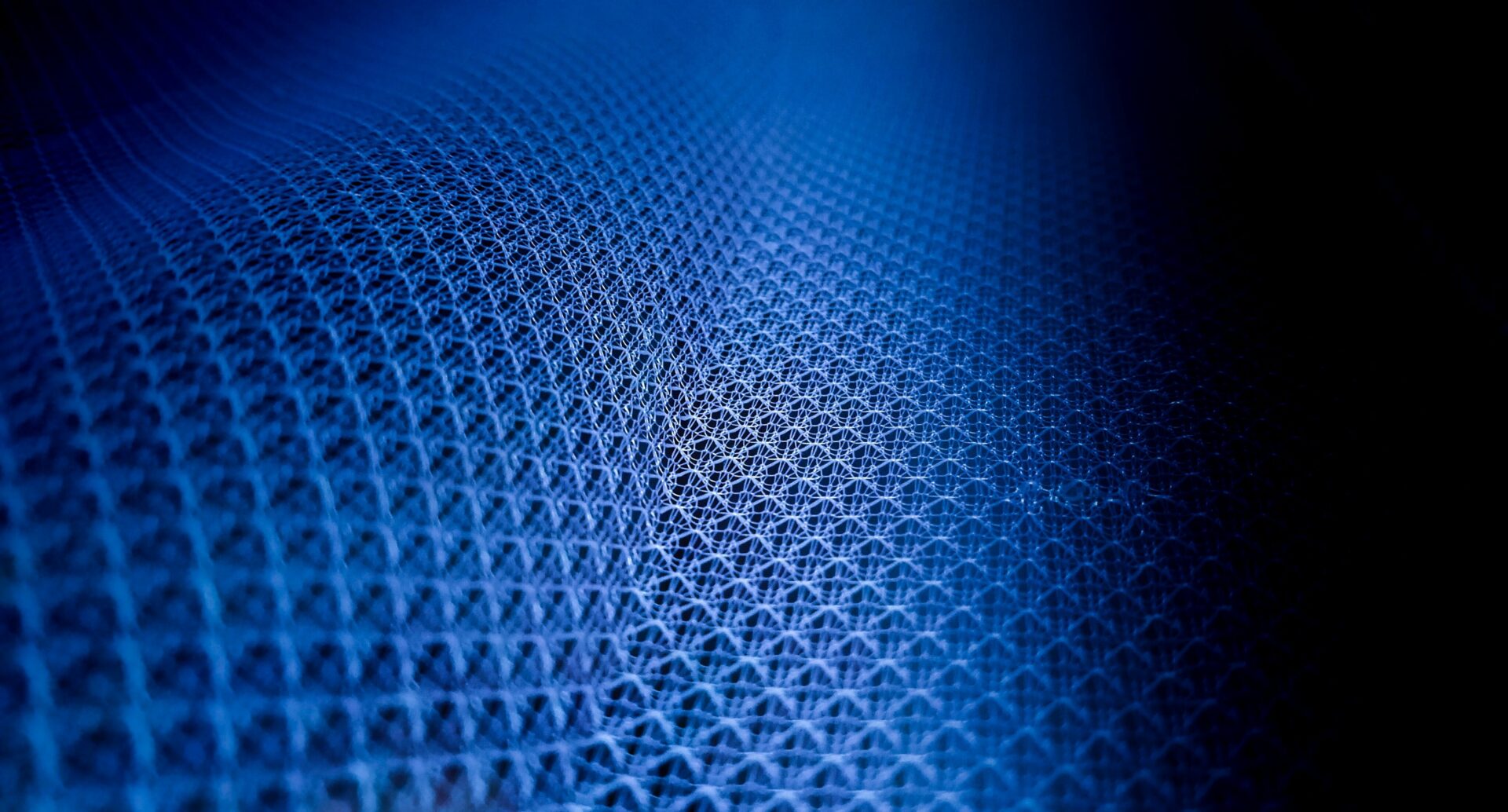

A “knitting net”, sometimes known as a “raschel net,” “knitted shade net,” or “sunshade net knitting,” is made from high-density polyethylene (HDPE) yarns that are interlaced using a knitting process — similar to how yarn is woven in textiles — rather than the conventional weaving or extrusion method. This knitting technique gives the net superior strength, flexibility, and multidirectional tension resistance, making it ideal for demanding industrial and agricultural applications.

At Siamnet Industries Co., Ltd., a trusted knitting net manufacturer in Thailand, knitting net that produce from our factory can be customized in order to match with various functional needs. These include safety nets for construction, cargo cover nets, and aquaculture nets — all engineered for safety, elasticity, and long-term durability far beyond typical woven mesh products available in the market.

High-Performance Fibers and Quality Control

Our knitting net in Thailand is crafted using high-grade HDPE yarns that undergo rigorous selection and quality testing, particularly focused on tensile strength — a crucial indicator of fiber performance.

Throughout the production process, we implement a systematic quality control protocol. Samples are tested according to ASTM D5034 standards, measuring tensile force while also examining the knit pattern and fabric density to ensure uniformity and reliability across every roll delivered to our clients.

To further enhance long-term durability, each knitted shade net is produced using HDPE yarns that include specialized stabilizers and additives:

-

UV Stabilizer – protects against ultraviolet degradation during prolonged outdoor use.

-

Antioxidants – slow down polymer deterioration caused by heat and oxygen exposure.

-

Antistatic Agents – prevent dust adhesion, making the net cleaner and easier to maintain.

Adaptability to Harsh Environments

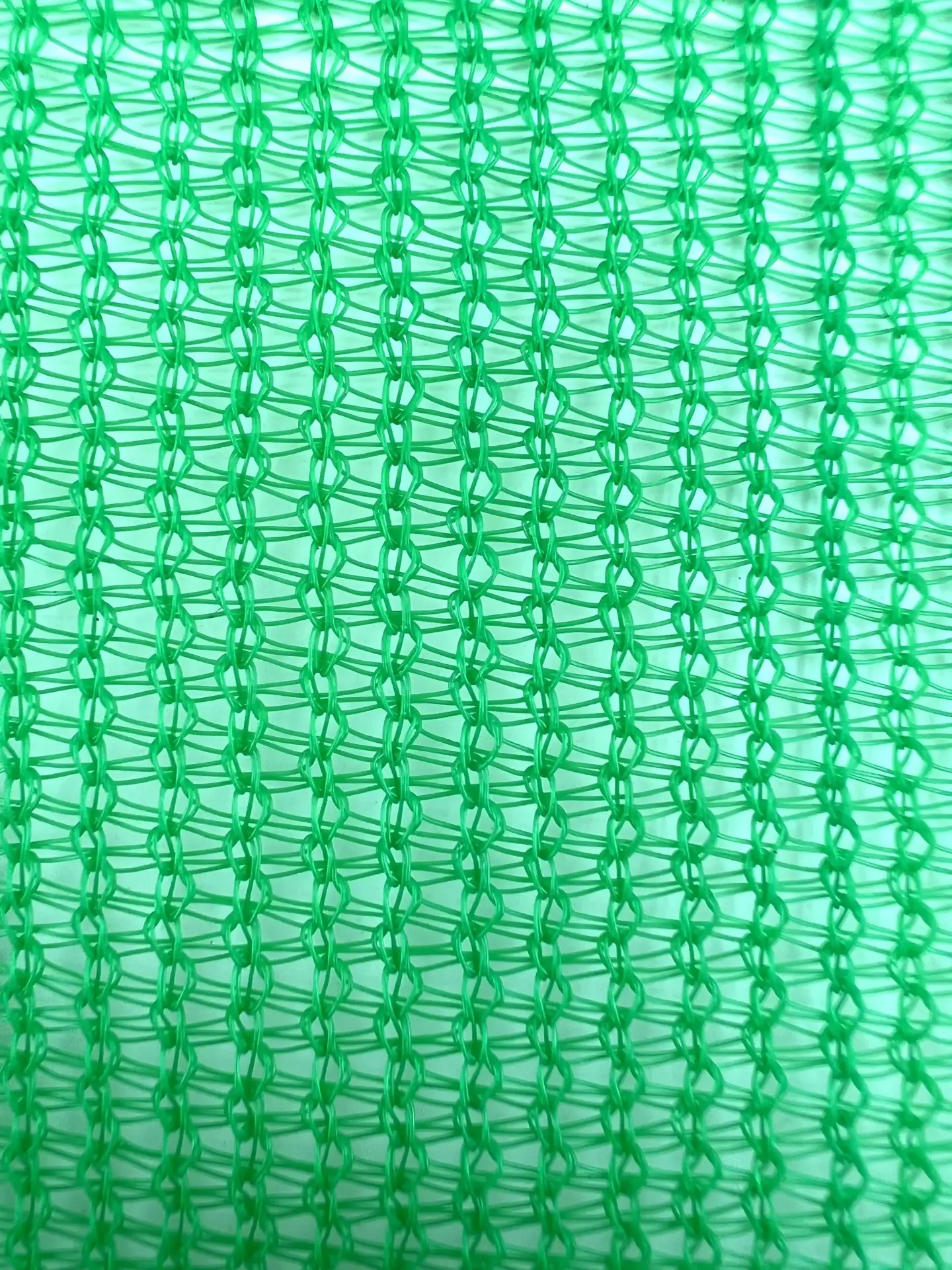

The HDPE knitted net is exceptionally suited for high-humidity or underwater environments, such as fish cages, pond enclosures, or marine farming, due to the following characteristics:

-

Non-absorbent – prevents swelling or deformation when exposed to water.

-

Rot-resistant – maintains strength and texture even after prolonged submersion.

-

Shape-retentive – does not stretch or sag under moisture, ensuring dimensional stability.

-

Non-rebound property – absorbs impact without recoiling, minimizing risks of damage or injury.

These properties enable the net to maintain its structure and functionality over time, even under challenging conditions. Moreover, it offers better resistance to saltwater corrosion and chemical degradation compared to conventional fibers such as nylon or polyester, which often soften or lose integrity in damp or submerged environments.

Additionally, underwater installations are not exposed to direct sunlight, reducing UV deterioration and thus extending the product’s service life even further.

Quality Inspection Before Delivery

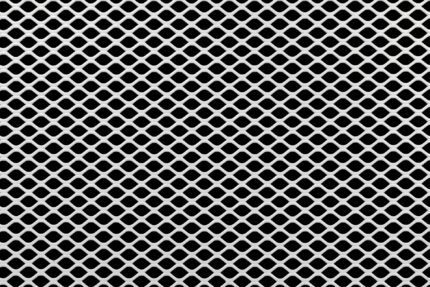

As a trusted knitting net supplier, we perform thorough inspections to ensure every product meets international standards before shipment. The quality checks cover:

-

Structural and Pattern Inspection – every roll is rechecked post-production for defects or inconsistencies before careful packing and dispatch.

-

Tensile Strength Testing – performed using ASTM D5034-certified machines to verify that the net can endure operational tension effectively.

-

Color and Fabric Uniformity Check – ensuring consistent hue and texture across the entire raschel net.

With years of expertise as a knitting net factory in Thailand, we continuously strive to deliver high-performance knitted nets designed for durability, versatility, and value — the perfect balance between engineering precision and craftsmanship. Whether you need sunshade net knitting for agriculture or heavy-duty knitted shade net for construction, our products embody reliability woven into every thread.

Knitting Net Specifications

| Production Type | Product Characteristic | Width | Length | Mesh Width | Weight per Square Meter | Color |

|---|---|---|---|---|---|---|

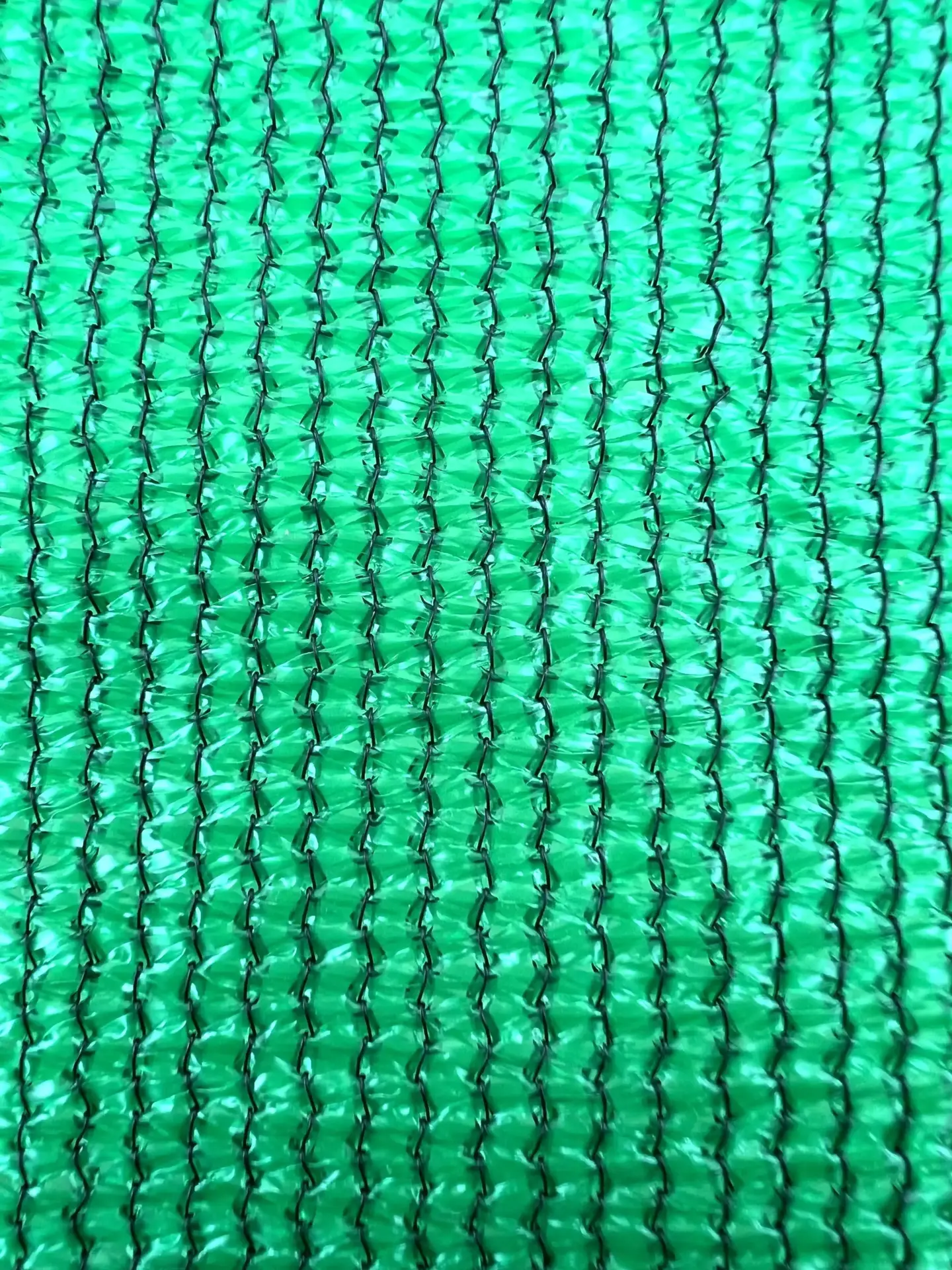

| Raschel Net (Model: M3) |  |

2m. – 4m. | 50m. – 100m. | – | 110g. – 135g. | Green / Grey |

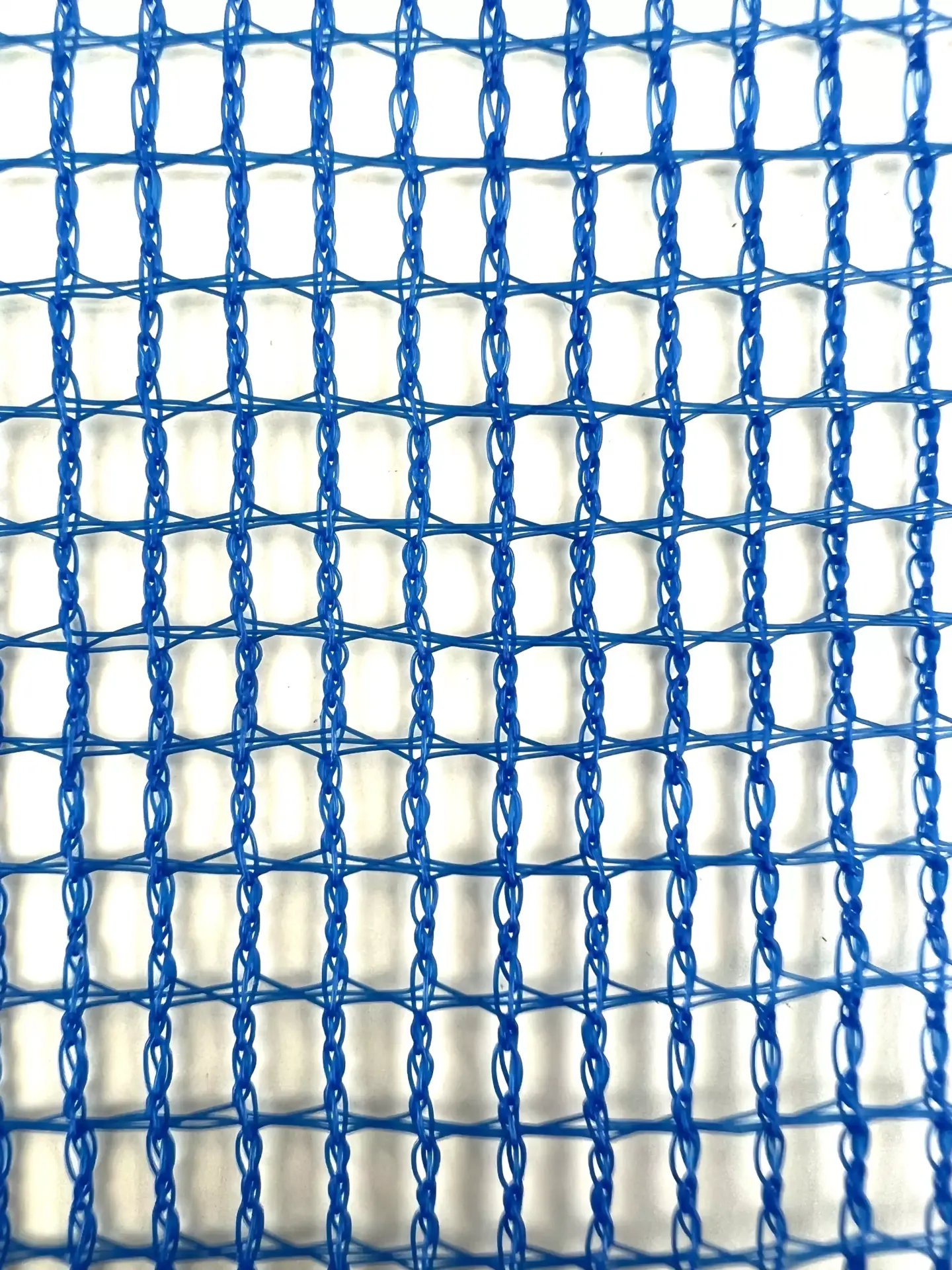

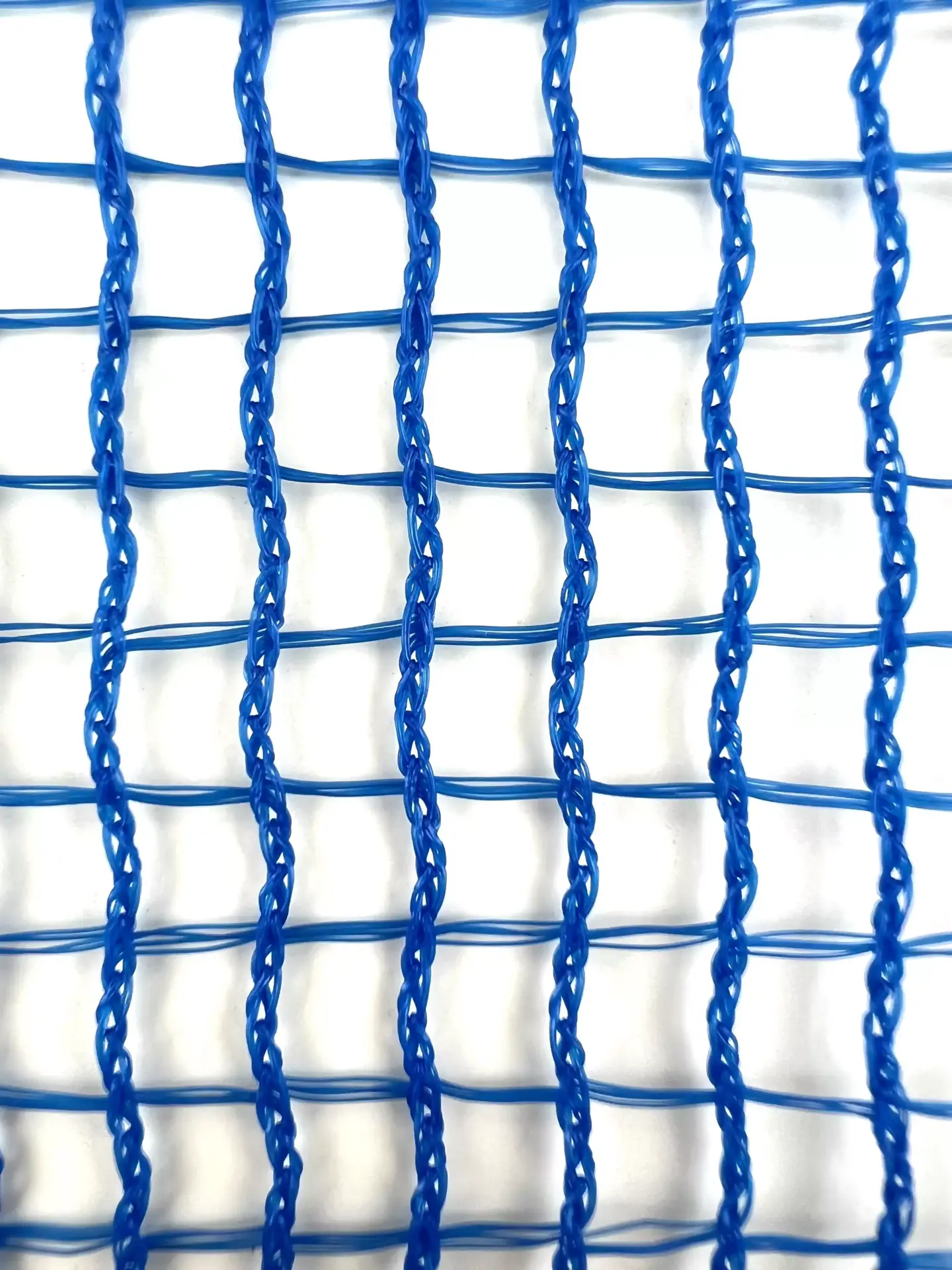

| Windbreak Net (Model: N4) |  |

1m. – 4m. | 30m. – 100m. | – | 90g. – 105g. | Blue |

| Windbreak Net (Model: N6) |  |

2m. – 4m. | 50m. – 100m. | – | 90g. – 100g. | Blue |

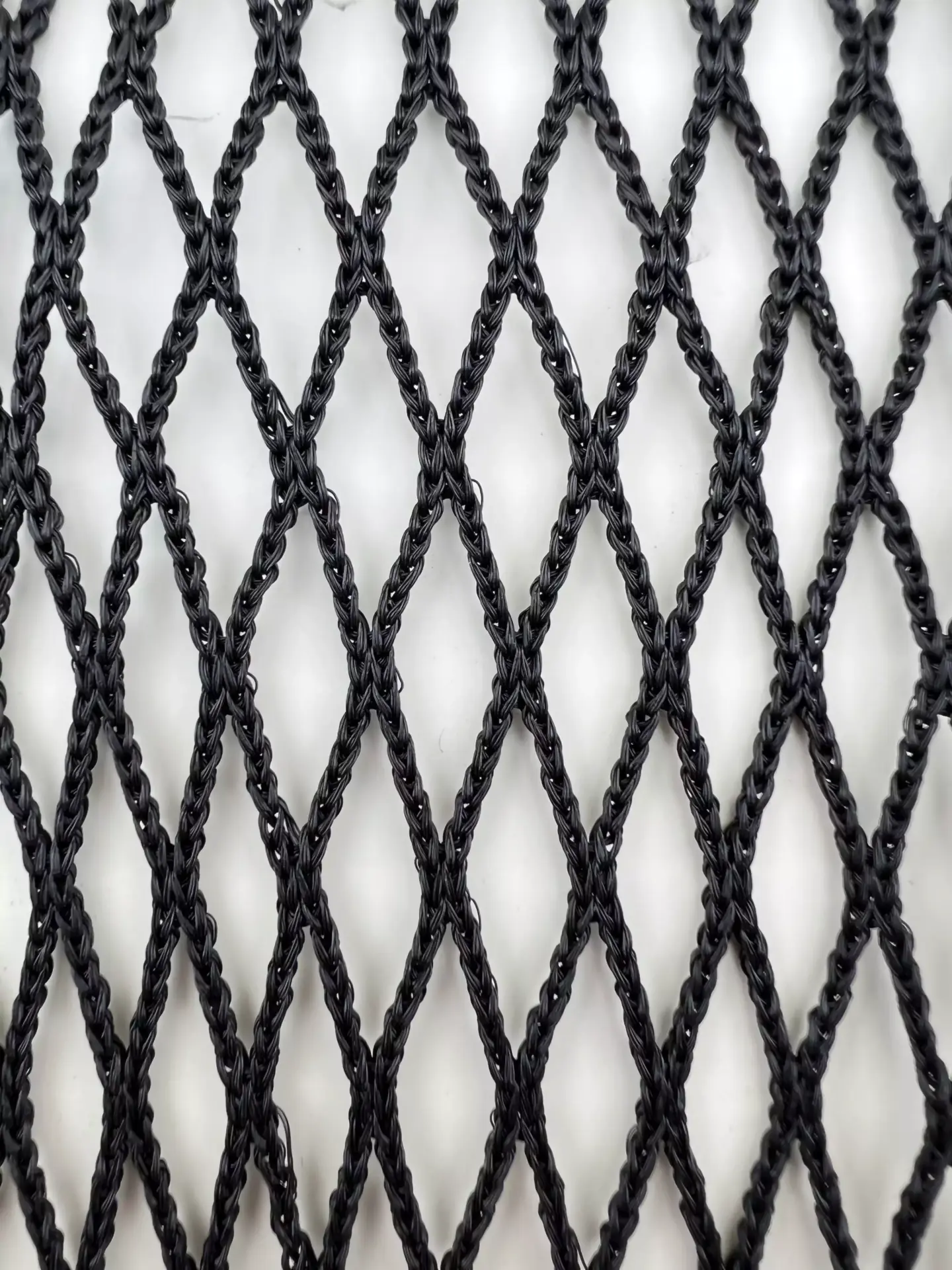

| Safety Net (Model: S6) |  |

300 mesh | 30m. – 50m. | 2cm. – 4cm. | – | Black |

| Knitted Shade Net (Model: F2) |  |

2m. – 4m. | 50m. – 100m. | – | 110g. – 195g. | Green / Black |

***The mesh pattern, color, thickness, and weight per square meter can be customized according to customer requirements, with a minimum order quantity of 10,000 meters.

Applications of Knitting Nets

Knitted net combines strength and flexibility in one durable material. Siam Net Industries Co., Ltd. designs high-quality knitted net for diverse uses — from agriculture and construction to sports and general applications. Built to resist sun and rain, they deliver reliable performance across multiple environments.

Shade nets help regulate sunlight in plant nurseries, creating optimal growing conditions by reducing heat and protecting plants from strong winds and certain insects. (Suitable Model: F2, M3, N4)

Commonly used in fish cages or as enclosure nets for aquaculture farms. Their strong yet flexible knitted structure makes them ideal for partitioning areas, separating nursery zones, and controlling the swimming direction of aquatic animals. (Suitable Model: N4, N6, S6)

Construction nets enhance on-site safety, serving as fall protection, safety nets, or windbreaks. Their knitted structure absorbs impact effectively and withstands harsh outdoor conditions. (Suitable Model: F2, M3, N4, S6)

Goal nets, golf course perimeter nets, and bird protection nets in sports facilities require strength and impact resistance, suitable for both indoor and outdoor use. (Suitable Model: S6)

Cargo nets prevent items from falling during land, sea, or air transport. Their strong, wind- and water-resistant structure makes them ideal for trucks, ships, and logistics. (Suitable Model: S6)

Marine nets are ideal for yachts, passenger, and commercial boats, used for drainage, deck areas, temporary partitions, lightweight structures, or as sea pool nets. (Suitable Model: S6)

Nets tested for all environmental conditions.

Our knitted nets are designed for diverse environmental usage, including agriculture, construction, and industries requiring long-term durability. They undergo both factory quality control and comprehensive field testing, including:

Durability testing: Nets are mounted on steel frames outdoors to evaluate resistance to sunlight, strong winds, and heavy rain, with continuous monitoring of fabric condition to accurately assess lifespan.

Load-bearing testing per square meter: Ensures our plastic nets are strong, safe, and suitable for applications such as construction barriers, industrial safety nets, or agricultural enclosures exposed to outdoor conditions.

We continually test and refine our manufacturing standards to maintain superior performance.