At Siamnet Industry, a shading net manufacturer in Thailand, we use 100% HDPE (High-Density Polyethylene) fibers as the primary raw material for our shade net production. This choice ensures long-term performance in terms of strength, flexibility, and resistance to sunlight and outdoor weather conditions.

Key Advantages Observed in Real Use

-

Excellent UV resistance — the material does not easily become brittle or cracked.

-

High elastic recovery — the net stays smooth and taut when stretched or installed.

-

Easy to fold, roll, and reshape without losing form.

During storage, users might notice that fibers in a roll appear loosely wound or slightly uneven. This is a natural behavior of flexible HDPE yarns and not a defect. Once stretched and installed, the fabric regains its perfect shape, thanks to its engineered knitting structure designed to withstand tension effectively.

By contrast, materials such as Polypropylene (PP) — whether 100% PP or blended PP/HDPE — may appear smoother and more compact during storage, but PP fibers typically have 1.5–2 times less UV resistance than HDPE.

According to polymer databases and material science research:

-

PP fibers used outdoors may degrade within 1–2 years.

-

HDPE fibers can last 3–5 years or more, depending on formulation and conditions.

Even when UV stabilizers are added, PP’s chemical structure remains prone to embrittlement under strong sunlight — particularly in tropical climates like Thailand.

Therefore, using 100% HDPE is not merely about quality — it’s about long-term reliability.

We believe outdoor fabrics should offer more than just good looks on a roll — they must be durable, functional, and built to last.

When Durability Comes from More Than HDPE Alone

To ensure optimal performance under diverse environmental conditions — including strong sunlight, dust, humidity, and continuous friction — our shade nets are enhanced with high-quality additive substances integrated directly during yarn extrusion.

These additives act as molecular-level shields, extending the lifespan of each fiber:

-

UV Stabilizer: Protects fibers from UV-induced degradation.

-

UV Absorber: Absorbs UV energy and minimizes heat buildup.

-

Antioxidants: Prevent oxidation that causes polymer brittleness.

-

Antistatic Agents: Reduce static electricity and help resist dust accumulation.

Some low-cost shade nets on the market may include calcium compounds to increase weight and reduce production costs. However, excessive calcium weakens the fiber structure, making it brittle and prone to cracking — especially under prolonged sunlight.

That’s why Siam Net Industries uses only additives that enhance performance without compromising quality, ensuring our nets are truly built for outdoor endurance.

Flat Yarn Technology: The Secret to Strength and Smooth Shading

Flat yarn, a tape-like filament, gives the shading net a tighter surface, better light diffusion, and a comfortable level of shade.

Our flat yarns are made from 100% HDPE, offering:

-

Excellent elasticity and UV resistance

-

Long-lasting durability

-

Smooth, dense texture for even shading

-

Free from calcium compounds, which can add weight but reduce flexibility and UV tolerance

HDPE vs. PP: Fiber Material Comparison

| Fiber Type | Advantages | Limitations |

|---|---|---|

| 100% HDPE Flat Yarn | • High UV resistance • Long lifespan • Smooth texture and soft light diffusion • Non-brittle under sunlight |

• More complex production process • Slightly higher cost |

| PP/HDPE Blended Yarn | • Easy to weave • Smooth and neat when rolled |

• Shorter lifespan • Degrades faster even with UV stabilizers • Brittle under heat |

| Calcium-Compound Blended Yarn | • Low cost • Heavier weight gives illusion of density |

• Very brittle • Poor UV resistance • Rapid degradation under outdoor exposure |

Shade Factor: Adjusting Light Like a Camera Aperture

One of the most important features of shade nets is the Shade Factor — the percentage of sunlight filtered through the fabric. It functions similarly to a camera aperture:

a higher shade factor means less light penetration and denser shade.

Siamnet Industry offers both woven and knitted shading nets with multiple light-filtering options:

-

Woven type: 50%, 60%, 70%, 80%

-

Knitted type: 90%, 95%

-

Custom options: available upon request (e.g., 85% or 92%)

Choosing the Right Shade Factor for Your Application

The ideal shade percentage depends on several factors — plant type, location, purpose, and user comfort.

Based on data from the FAO, ShelterProjects.org, and field experience:

| Shade (%) | Light Transmission (%) | Recommended Use |

|---|---|---|

| 30–50% | 70–50% | Sun-loving crops (lettuce, seedlings, tomatoes) |

| 50–70% | 50–30% | Moderate-light plants (flowers, ornamentals, fruit trees) |

| 70–90% | 30–10% | Low-light uses (mushroom farms, car parks, outdoor work areas) |

| 90–95% | 10–5% | High-shade areas (playgrounds, passenger shelters, rest stops) |

Did You Know?

The right shade net can do much more than provide shade:

✅ Creates a microclimate ideal for plants and human comfort

✅ Reduces heat and water evaporation, saving energy in greenhouses and farms

✅ Protects vehicles, tools, and outdoor furniture from UV damage

✅ Extends the lifespan of spaces and reduces maintenance costs

Choosing the correct shade factor means designing comfort and sustainability into your environment.

Choose Premium Shading Nets from Siamnet Industry

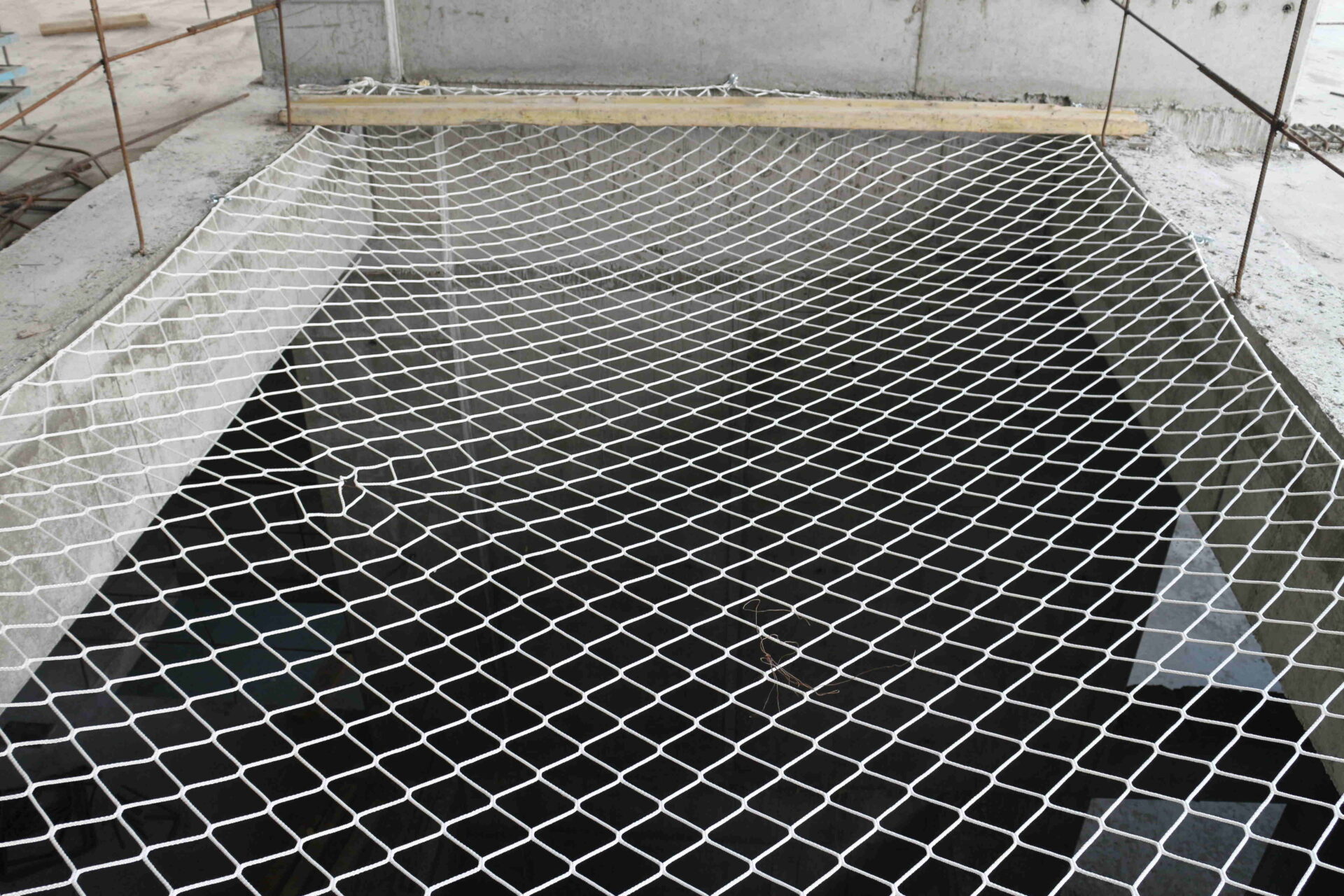

A high-quality shading net begins with strong, consistent yarn capable of withstanding high tension and harsh sunlight.

That’s why we continuously monitor the quality of our HDPE flat yarns, ensuring every roll meets industrial standards for durability, flexibility, and long service life — ready for any outdoor condition.

Reference

- Different Types of Knitted Shade Net and Their Uses. Retrieved on September 17, 2025, from Different Types of Knitted Shade Net and Their Uses – OMB Textiles

- Polyethylene vs Polypropylene: When to Choose What?. Retrieved on September 17, 2025, from Polyethylene vs Polypropylene ( PE vs PP ): A Comprehensive Comparison Guide