The structure of a rope is the heart of its performance. Whether it’s made through twisting or braiding, the manufacturing process directly affects a rope’s strength, flexibility, and suitability for specific applications.

1. Twine Rope: Durable and Easy to Use

Twine rope is one of the most popular rope types, widely used in agriculture, industry, transportation, and general applications. Its main advantages are strength, durability, and ease of use, making it a standard choice across various sectors.

Twine ropes are made by twisting synthetic fibers together, often using a multi-level twisting process to achieve the desired diameter and tensile strength. Although it may appear as a single strand, the internal layers are meticulously twisted to create a tight, balanced, and strong rope.

Designed Twist Structure for Maximum Strength

-

Twisting fibers into strands distributes tension evenly.

-

Tight twists yield a stronger, more stable rope with minimal stretch.

-

Loose twists result in softer ropes with more flexibility but lower tensile strength.

-

Ideal for tying, pulling, lifting, or creating secure barriers.

Standard Twine Rope Structures

3-Strand Rope:

- Three main strands twisted together without a core.

- Advantages: High tensile strength per strand, strong and compact.

- Widely used worldwide.

4-Strand Rope:

- Four strands twisted together with a core to balance the structure.

- Advantages: Good flexibility and shape retention.

- Popular in Southeast Asia.

Comparison of 3-Strand vs. 4-Strand Twine Rope

| Rope Type | Highlights | Considerations |

|---|---|---|

| 3-Strand Rope | Large strands, distributes weight in 3 directions, stronger than equivalent 4-strand rope | Less flexible, may twist if strands are loose |

| 4-Strand Rope | Core maintains balance, flexible, good shape retention | Smaller strands → lower tensile strength, quality must be controlled to prevent loosening |

Quality Criteria for Twine Rope

-

Twist does not unravel when cut.

-

Maintains shape when bent into a U-shape.

-

No gaps or inconsistencies along the rope.

-

Smooth, firm texture without roughness.

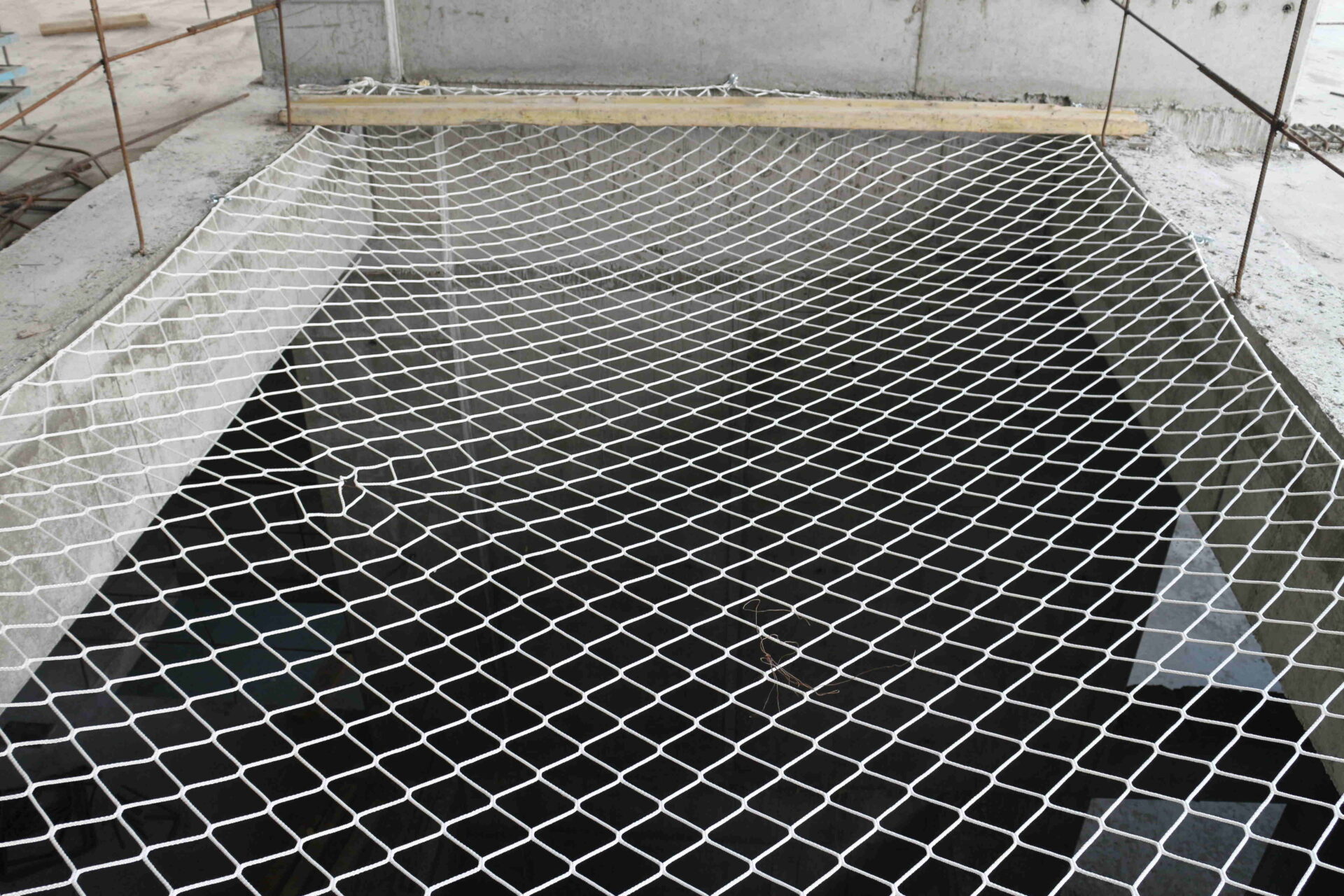

2. Braided Rope: Strength with Flexibility

Braided ropes combine softness, strength, and flexibility in a single strand. The fibers are interwoven in complex patterns, similar to a braid, which distributes tension evenly, reduces twisting, and maintains shape under repeated use.

Braided Rope Structures

-

Solid Braided Rope: Dense and uniform, smooth surface, minimal twisting. Ideal for medium to high tension applications, such as tying or decorative purposes.

-

Hollow Braided Rope: No core, lightweight and flexible. Can insert reinforcement later. Ideal for temporary or adjustable uses.

-

Double Braided / Kernmantle Rope: Core absorbs tension, outer sheath protects and adds flexibility. Suitable for heavy-duty work like climbing, industrial lifting, or rigging.

Quality Criteria for Braided Rope

-

Tight and orderly braid pattern.

-

Durable fibers with no fraying.

-

Quick shape recovery after use.

-

Soft texture suitable for direct handling.

-

Stable structure after cutting to prevent unraveling.

Twine Rope vs. Braided Rope: Which is Right for You?

Selecting the right rope depends not only on size or material but also on its manufacturing structure, which affects real-world performance.

| Feature | Twine Rope | Braided Rope |

|---|---|---|

| Structure | Twisted fibers into tight strands | Interwoven fibers in braided patterns |

| Flexibility | Strong but may twist | Retains shape, resists twisting |

| Feel | Firm and dense | Soft and flexible |

| Strength | Good tensile strength, ideal for pulling/tieing | Handles shock loads, distributes tension |

| Applications | Agriculture, construction, cargo handling | Climbing, rigging, industrial lifting |

| Appearance | Visible twist grooves, rugged | Smooth, consistent surface |

| Durability | Excellent under constant tension | Excellent under movement and shock |

Summary:

-

Choose Braided Rope if you need softness, shape retention, and even tension distribution.

-

Choose Twine Rope if you need strength, tight grip, and cost efficiency.

Both types can be made from HDPE or PP fibers, depending on your application. Siamnet Industry, a trusted PP rope manufacturer, provides professional advice to help you select the best rope for your needs across all sectors.

Reference

- “Rope | Climbing, Boating & Industrial Applications.” Retrieved on September 17, 2025, from Rope | Climbing, Boating & Industrial Applications | Britannica

- “3-Strand or 4-Strand Rope?” Retrieved on September 17, 2025, from 3-Strand or 4-Strand Rope?