Siamnet Industry Co., Ltd.

We are a leading manufacturer of mosquito nets, plastic mesh, and various related products such as shade nets, safety nets, and other materials designed to meet the needs of multiple industries — including agriculture, manufacturing, construction, and logistics.

With our strong commitment to quality throughout the production process, our products have earned the trust of customers both domestically and internationally. Moreover, we continuously strive to develop and test our products to ensure that every item meets the highest standards of quality and performance.

Premium Nylon Screen Net for Insect Protection & Greenhouses

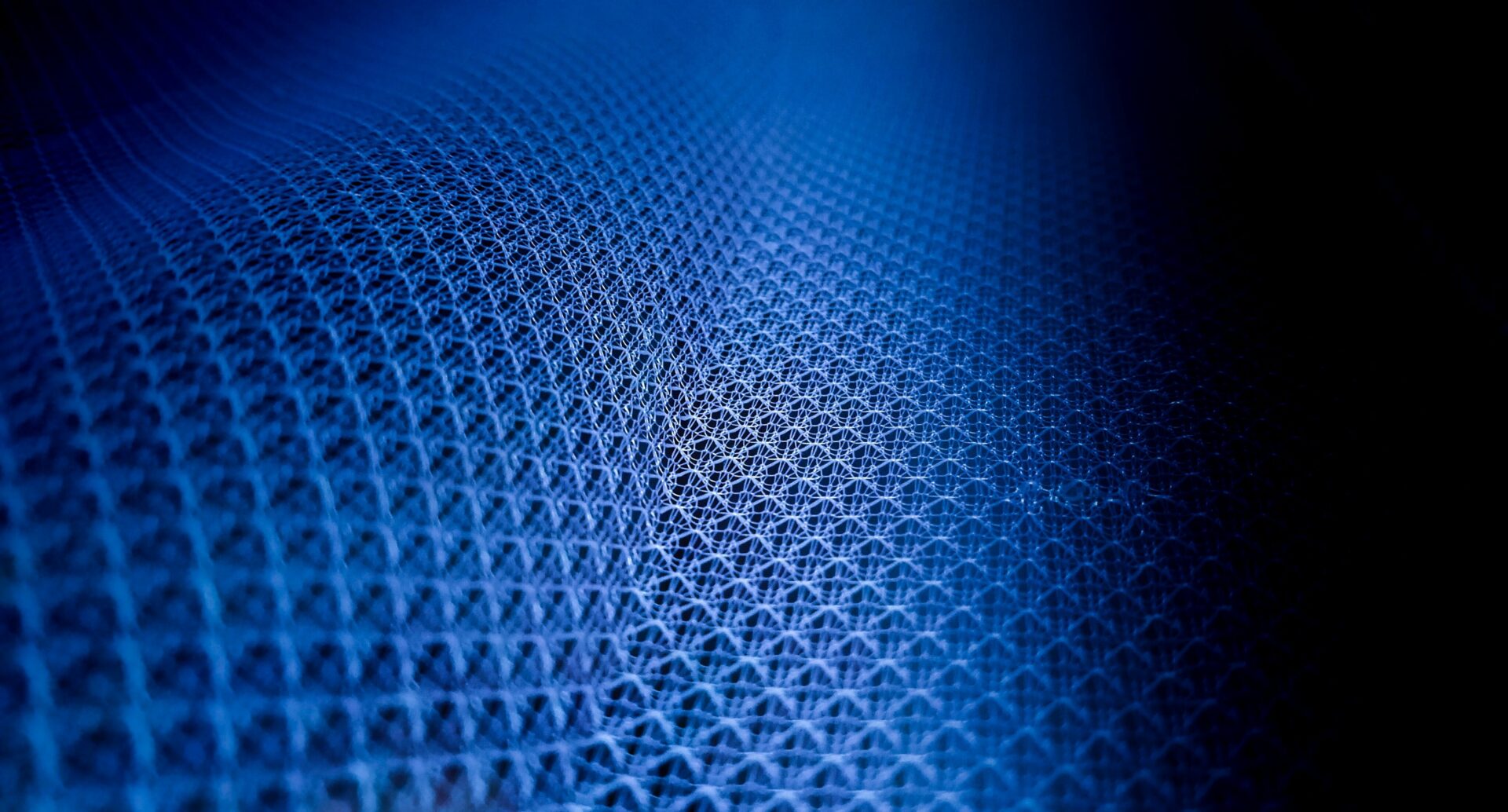

Mosquito Screen Net (also known as Insect Screen Net, Mosquito Wire Screen, Blue Net, or PE Screen Net)

is a high-quality synthetic mesh made from High-Density Polyethylene (HDPE), designed for strength, flexibility, and long-term durability. As a leading screen net factory in Thailand, we specialize in producing various types of screen nets that meet both industrial and household needs. Our products are lightweight, transparent, and highly breathable, while also being resistant to sunlight, rain, and humidity — making them ideal for use in Thailand’s tropical climate.

Thanks to these exceptional properties, screen net in Thailand has become an essential material across multiple industries — from agriculture, greenhouses, livestock farms, and fisheries to DIY and general household use. It provides outstanding performance in protecting crops, livestock, and spaces from insects and pests while ensuring effective airflow and light transmission.

Fiber Production Standards

At Siamnet Industries Co., Ltd., a trusted screen net manufacturer in Thailand, we divide our screen net production into two distinct quality grades to meet different applications and budgets:

-

Standard Grade:

Meets general industrial standards, suitable for indoor use or temporary installations. -

Premium Grade:

Features enhanced tensile strength and UV resistance for outdoor or long-term use, offering superior weather durability and longer lifespan.

Every screen net we produce is made from high-quality raw materials under strict quality control to ensure that each roll is strong, flexible, and ready for real-world applications.

Coloring and Additive Protection

To maintain both beauty and performance, our screen net uses advanced additive technologies:

-

Color Masterbatch: Ensures consistent color tones that resist fading and peeling, with safe and eco-friendly pigments.

-

UV Stabilizers: Extend the product’s lifespan during continuous outdoor exposure.

-

Antioxidants and Antistatic Agents: Strengthen the polymer fibers and reduce dust accumulation during use.

Among our product range, the Blue Net and PE Screen Net are especially popular choices for agricultural and greenhouse use due to their durability and excellent ventilation performance.

Production Process and Quality Inspection

As a professional screen net factory in Thailand, we implement a comprehensive quality assurance process to ensure our screen net meet international standards. We focus on four main inspection areas:

-

Mesh Size Measurement:

Using precision instruments to ensure consistent and accurate mesh openings. -

Tensile Strength Testing:

Conducted according to ASTM D5034 standards to guarantee high durability and performance under tension. -

Fabric and Color Uniformity:

To ensure smooth texture, even color, and no manufacturing defects. -

Outdoor Durability Testing:

Real-world field tests under sunlight, wind, and rain to evaluate lifespan and UV resistance.

Product Options – Choose What Fits Your Needs

-

Standard Grade: Suitable for short-term or general use, with an average lifespan of 2–3 years.

-

Premium Grade: Designed for heavy-duty outdoor applications, lasting approximately 5–8 years.

Note: Product lifespan may vary depending on environment, installation method, and maintenance conditions.

If you’re looking for a trusted screen net factory in Thailand that offers high-quality insect screen nets, mosquito screen nets, and PE screen nets designed for all industries — from agriculture to construction — Siamnet Industries Co., Ltd. is your reliable partner for durable and high-performance screen net solutions.

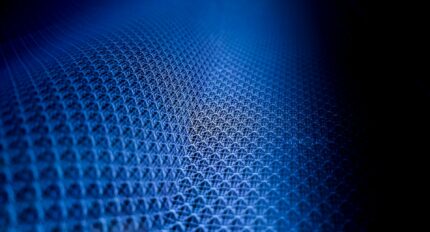

Durable & Strong Knitting Net Made from HDPE Fibers

A “knitting net”, sometimes known as a “raschel net,” “knitted shade net,” or “sunshade net knitting,” is made from high-density polyethylene (HDPE) yarns that are interlaced using a knitting process — similar to how yarn is woven in textiles — rather than the conventional weaving or extrusion method. This knitting technique gives the net superior strength, flexibility, and multidirectional tension resistance, making it ideal for demanding industrial and agricultural applications.

At Siamnet Industries Co., Ltd., a trusted knitting net manufacturer in Thailand, knitting net that produce from our factory can be customized in order to match with various functional needs. These include safety nets for construction, cargo cover nets, and aquaculture nets — all engineered for safety, elasticity, and long-term durability far beyond typical woven mesh products available in the market.

High-Performance Fibers and Quality Control

Our knitting net in Thailand is crafted using high-grade HDPE yarns that undergo rigorous selection and quality testing, particularly focused on tensile strength — a crucial indicator of fiber performance.

Throughout the production process, we implement a systematic quality control protocol. Samples are tested according to ASTM D5034 standards, measuring tensile force while also examining the knit pattern and fabric density to ensure uniformity and reliability across every roll delivered to our clients.

To further enhance long-term durability, each knitted shade net is produced using HDPE yarns that include specialized stabilizers and additives:

-

UV Stabilizer – protects against ultraviolet degradation during prolonged outdoor use.

-

Antioxidants – slow down polymer deterioration caused by heat and oxygen exposure.

-

Antistatic Agents – prevent dust adhesion, making the net cleaner and easier to maintain.

Adaptability to Harsh Environments

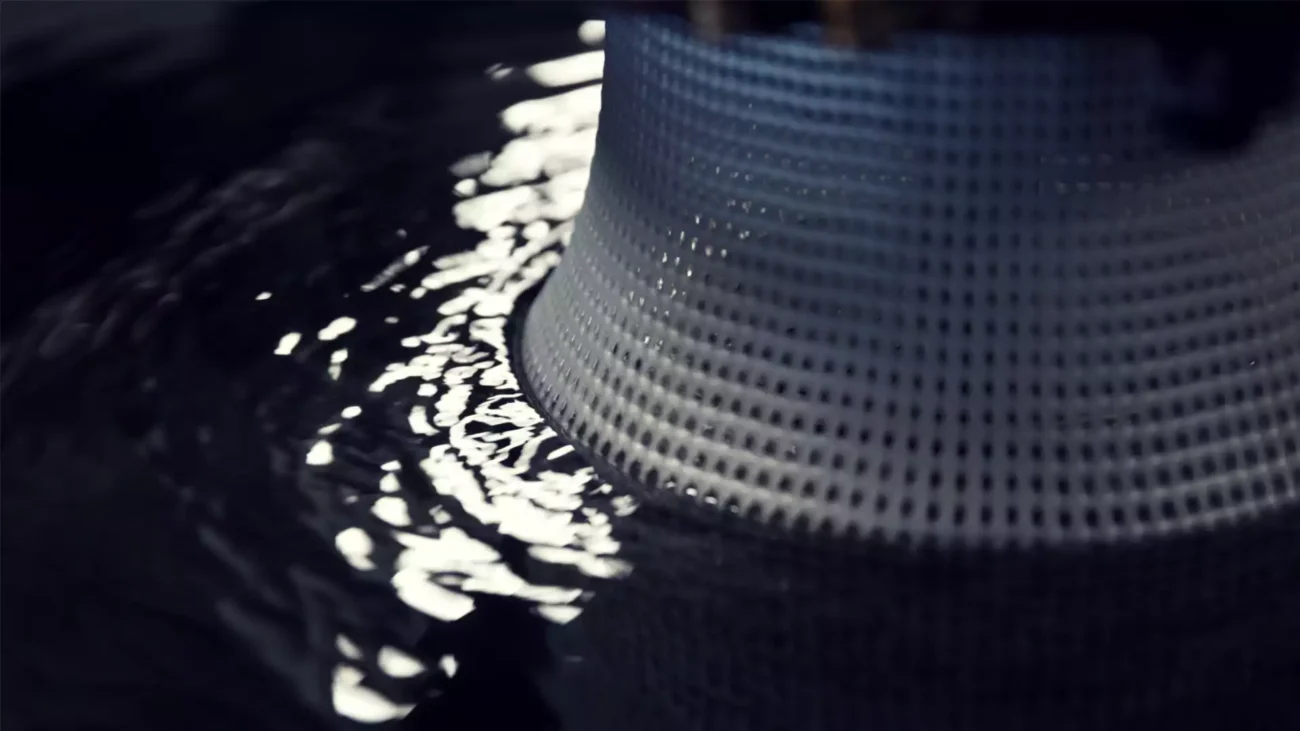

The HDPE knitted net is exceptionally suited for high-humidity or underwater environments, such as fish cages, pond enclosures, or marine farming, due to the following characteristics:

-

Non-absorbent – prevents swelling or deformation when exposed to water.

-

Rot-resistant – maintains strength and texture even after prolonged submersion.

-

Shape-retentive – does not stretch or sag under moisture, ensuring dimensional stability.

-

Non-rebound property – absorbs impact without recoiling, minimizing risks of damage or injury.

These properties enable the net to maintain its structure and functionality over time, even under challenging conditions. Moreover, it offers better resistance to saltwater corrosion and chemical degradation compared to conventional fibers such as nylon or polyester, which often soften or lose integrity in damp or submerged environments.

Additionally, underwater installations are not exposed to direct sunlight, reducing UV deterioration and thus extending the product’s service life even further.

Quality Inspection Before Delivery

As a trusted knitting net supplier, we perform thorough inspections to ensure every product meets international standards before shipment. The quality checks cover:

-

Structural and Pattern Inspection – every roll is rechecked post-production for defects or inconsistencies before careful packing and dispatch.

-

Tensile Strength Testing – performed using ASTM D5034-certified machines to verify that the net can endure operational tension effectively.

-

Color and Fabric Uniformity Check – ensuring consistent hue and texture across the entire raschel net.

With years of expertise as a knitting net factory in Thailand, we continuously strive to deliver high-performance knitted nets designed for durability, versatility, and value — the perfect balance between engineering precision and craftsmanship. Whether you need sunshade net knitting for agriculture or heavy-duty knitted shade net for construction, our products embody reliability woven into every thread.

High Quality Shading Net — Enhances the Environment

In agriculture, industry, and even household usage, shading nets are far more than just materials for sun protection or light filtering. A high-quality shading net helps reduce heat inside greenhouses, protect crops from excessive sunlight, and control temperature in industrial yards. That’s why a shading net plays an essential role in creating a comfortable and efficient environment for every application.

Unlike conventional materials, shading nets are engineered to balance not just the amount of light but also the quality and direction of light — factors that directly affect plant growth, visibility, and shading efficiency in different settings.

At Siamnet Industry, we manufacture our products using 100% High-Density Polyethylene (HDPE) yarn, ensuring long-lasting strength, flexibility, and resistance to UV rays and harsh weather. As a trusted shading net factory in Thailand, our products are widely recognized for their superior performance and durability.

Key advantages include:

-

Excellent UV resistance without becoming brittle or fragile

-

Stable and smooth tension when installed

-

Easy to fold, roll, or shape without deformation

Two Main Types of Shading Net Structures

1. Woven Structure

Produced using the same technique as textile weaving, this type consists of two main components:

-

Warp yarns: round HDPE monofilaments providing structure and tension

-

Weft yarns: flat HDPE yarns allowing flexibility and an even surface

This design ensures consistent shading density and prevents fiber loosening over time. It is widely used as a black shading net or shading net for greenhouse applications requiring clean appearance and even light distribution.

2. Knitted Structure

These feature intricate weave patterns that enhance both strength and flexibility. They are ideal for areas requiring broad coverage without rigid frameworks—such as greenhouses, windy environments, or design projects that demand unique shapes.

The knitted structure can also be customized with specific patterns, such as diagonal weaves, grid designs, or semi–double-layer shades, to achieve targeted light filtration and aesthetic effects. Patterns like diagonal, grid, or double-layer knitting can be customized, making it a popular choice for both construction net and shading net for plants.

Quality Control and Testing

As a shading net manufacturer and shading net supplier, we maintain rigorous quality standards:

-

Tensile strength testing under ASTM D2256 to ensure durability under real-world conditions

-

Field testing under sunlight, strong winds, humidity, and open-air exposure to analyze fiber performance

-

Continuous product development based on customer feedback and in-house trials

Dual Expertise — Weaving and Knitting Technology

Our production combines the strengths of both woven and knitted manufacturing systems, ensuring the perfect balance between functionality, appearance, and durability.

Woven Shading Net Advantages:

-

Smooth surface with uniform light diffusion

-

Excellent shape retention when installed

-

Available in various shading levels (50–80%)

Knitted Shading Net Advantages:

-

High elasticity and flexibility

-

Customizable patterns and densities (90–95% shading)

*Ideal for Safety Net, Dust Prove Net, Wind Prove Net, and Fish Cage Net applications

At Siamnet Industries, we’re proud to be a trusted shading net manufacturer in Thailand. With our technical expertise and innovative approach, we produce high-quality green and black shading nets that provide reliable protection, shade, and durability—wherever they’re needed most.

Rope Manufacturer for Agriculture, Delivering Top Quality Products

Rope may seem simple, but it plays a crucial role across various applications—from agriculture, industry, and fishing to construction and everyday household use. The difference in rope quality lies not only in its “appearance” or “material” but also in its manufacturing structure, fiber selection, and underlying quality standards.

At Siamnet Industry, we design ropes specifically for their intended use, selecting premium materials and employing meticulous production processes. Each rope undergoes comprehensive performance testing, ensuring strength, durability, and safety—no matter how demanding the working conditions. As a trusted PP rope manufacturer and PP rope supplier, we deliver industrial grade rope that you can rely on.

Carefully selected high-quality fibers

The fiber is the heart of rope production. For ropes that must withstand real-world tension under harsh sun, strong winds, or fluctuating environments, choosing the right fiber is the foundation of reliability.

Siamnet Industries produces synthetic fibers in-house to maintain consistent quality and performance. We primarily use two types of fibers suitable for various industrial applications:

-

PP Rope (Polypropylene)

-

Lightweight

-

Ideal for fruit tying and general agricultural usage

-

Cost-effective and suitable for short-term applications

-

-

PE / HDPE Rope (High-Density Polyethylene)

-

High UV resistance, not easily brittle

-

Perfect for outdoor use, tent installations, or applications requiring long-term durability

-

Excellent shape retention; resists stretching even in humid conditions

-

Enhanced durability through additives

High-quality additives are blended into the fibers during production to provide molecular-level protection, ensuring that our ropes are strong, durable, and ready for any application:

-

UV Stabilizers: Prevent ultraviolet radiation from breaking down polymer structures, keeping ropes from becoming brittle or cracking in prolonged sun exposure.

-

Antioxidants: Slow oxidation reactions that can prematurely degrade fibers, especially in high-temperature environments.

-

Antistatic Agents: Reduce static build-up on the rope surface, preventing dust accumulation and keeping the rope cleaner and safer to handle.

Criteria for high-quality rope

To ensure reliable performance, consider the following qualities:

-

Consistent braiding: Tight, even braiding without loose sections or unraveling along the rope.

-

No protruding fibers or frays: Reflects strict quality control during manufacturing.

-

Good shape retention under tension: Maintains original form without sagging after repeated use.

-

Smooth texture: Comfortable to handle without cutting or irritating hands.

-

Stable structure when cut: Well-balanced design prevents fraying or structural failure during real-world use.

High-Quality Brush Bristle Manufacturer for All Applications

Brush Filament refers to the synthetic fibers engineered for use in various types of brushes—ranging from cleaning brushes, industrial brushes, and paint brushes to medical and specialized equipment. The flexibility, durability, and material composition of each filament type directly influence the brush’s overall performance and lifespan.

For industrial applications, selecting high-quality bristles ensures reduced wear, improved surface precision, and long-term cost efficiency—especially in operations that demand resistance to pressure, abrasion, or repetitive use.

Material Expertise in Manufacturing Bristle

At Siamnet Industry, a trusted brush bristles manufacturer and bristles supplier in Thailand, we produce filaments from Polypropylene (PP) and High-Density Polyethylene (HDPE)—two materials with distinct performance characteristics:

-

PP (Polypropylene): Lightweight yet strong, chemical-resistant, and moderately flexible—ideal for general-purpose brushes requiring a balanced softness and stiffness.

-

HDPE (High-Density Polyethylene): Offers superior durability and rigidity, making it suitable for heavy-duty applications such as industrial floor brushes and machinery cleaning brushes.

Over 35 Years of Experience as a Leading Bristles Manufacturer in Thailand

Siamnet Industry has been manufacturing brush bristles since 1989, gaining a deep understanding that a bristle is more than just a simple fiber — it is a critical component that demands precision, consistency, and continuous quality control throughout every stage of production.

Our expertise has been built through hands-on collaboration with clients from diverse sectors and ongoing technological improvement, ensuring that every filament we produce delivers consistent, high-performance results in real-world use.

Quality You Can See and Feel

Every production stage—from extrusion and cutting to bundling and packaging—is carefully monitored under our in-house quality assurance system, developed from over 35 years of manufacturing experience.

Our inspection standards cover:

-

Denier Control: Measured with precision tools, maintaining a deviation within ±9% of the specified median value.

-

Surface Finish Inspection: Each batch is tested to ensure smooth texture, free of bubbles, cracks, or impurities.

-

Hardness & Flexibility: Regularly tested to align with intended brush functionality.

-

Tensile Strength and Elongation: Tested in accordance with ASTM D3822 standards to ensure optimal durability and elasticity.

-

Precision Cutting & Packing: Bristles are cut evenly at both ends, bundled neatly, and packed for immediate use.

These meticulous processes not only enhance product longevity but also minimize waste and inefficiency during brush production and end use.

Custom Specifications & Technical Consultation

Whether you require bristles for metal polishing, general cleaning, or highly specialized industrial applications, Siamnet Industry provides end-to-end service—from prototype sampling and application analysis to customized mass production.

As a dedicated bristles supplier in Thailand, we ensure that every product is tailor-made to meet your specific requirements, offering both material recommendations and technical guidance to help you achieve optimal results.

Systematic Packing and Delivery

Once quality inspection is completed, bristles are packaged with precision to maintain their form, density, and usability during transit and storage:

-

Evenly trimmed ends

-

Packed in optimized bundles for protection and efficiency

-

Prevented from compression or deformation before delivery

These small yet crucial details ensure that our bristles are truly ready for use from the moment you open the package.

Siamnet Industry – Leading PP Weaving Sack Manufacturer

White Sack or Plastic Sack is one of the most versatile materials used for packing and wrapping products across agriculture, industry, and logistics. With its lightweight yet durable structure, this Weaving Sack has become the go-to solution for packing rice, fertilizer, grains, construction materials, or even for creative applications like eco-friendly bags and innovative packaging.

Because woven sacks are often exposed to frequent movement, moisture, and pressure, a good PP woven fabric bag must be strong, flexible, and resistant to various environmental conditions.

Premium Materials: PP + HDPE for Maximum Durability

At Siamnet Industry, our white pp woven bag is made from high-quality polymer fibers — Polypropylene (PP) and High-Density Polyethylene (HDPE) — to ensure superior strength and lasting performance.

-

PP (Polypropylene): Lightweight, flexible, and ideal for indoor general use.

-

HDPE (High-Density Polyethylene): Adds rigidity, shape retention, and excellent resistance to outdoor conditions.

By blending PP and HDPE in the right ratio, we produce woven sacks that are significantly stronger and more durable than standard PP-only bags — extending their lifespan even under tough conditions.

Comparison Between Siamnet Industry’s Woven Sacks and Conventional Plastic Sacks

| Feature | Siamnet Industry Woven Sack | Regular Woven Sack |

|---|---|---|

| Material | PP + HDPE or 100% HDPE | PP only |

| Lifespan | Up to 2× longer, UV & moisture resistant | Shorter lifespan, degrades faster in sun or humidity |

| Tensile Strength | Excellent tear & weight resistance | May fray or tear under heavy use |

| Moisture Protection | Naturally moisture-resistant, no coating needed | Often coated on only one side or not at all |

| Shape Retention | Easy to flatten and reshape | Becomes stiff, wrinkles easily |

Thanks to these qualities, our woven sacks are ideal for both general packing and heavy-duty industrial use, including storage, transportation, and agricultural applications involving moisture or repeated handling.

Available in Both Fabric and Ready-Made Bags

We are a PP woven bag manufacturer offering products in two main types:

-

Flat Sheet Fabric: For large surface wrapping or coverage.

-

Open-End Tubular Sack: Perfect for packing and shipping agricultural or industrial goods.

We also provide custom cutting and sewing services — from fertilizer bags and rice sacks to reusable shopping bags and other tailored designs.

Tailored to Your Specification

As a trusted PP woven bag supplier, Siamnet allows you to customize:

-

Width, length, and GSM (gram per square meter)

-

Open or closed ends, with or without stitches

-

Air vents, gussets, or handles

-

Printed logo or branding

All products are made-to-order with pricing based on design and quantity — ensuring flexibility for every business need.

Over 35 Years of Real Industry Expertise

With more than 35 years of experience, Siamnet Industry understands the real-world challenges our customers face. That’s why every White Sack and Plastic Sack we produce is designed for practical performance — built to withstand sun exposure, heavy loads, and long-term humidity.

Each production batch undergoes tensile testing, yarn consistency checks, and durability sampling to ensure that every PP sack bag and HDPE sack bag you receive is strong, reliable, and protects your products effectively.

Siamnet Industry: Durable Plastic Mesh for Various Uses

Plastic Mesh Net is a versatile material widely used in agriculture, construction, and packaging industries. It is known by various names depending on its application — such as plastic chicken mesh, plastic bird mesh, or mesh bags for fruits and vegetables.

At Siamnet Industry, our plastic mesh products are made from high-quality polymers — Polypropylene (PP) and Polyethylene (PE) — ensuring excellent strength, flexibility, and resistance to sunlight and moisture. These features make them ideal for outdoor use, farming, and long-term industrial applications.

Structure and Material Composition

Although all mesh nets serve similar functions, their durability and flexibility vary according to the stretching process, which directly affects the molecular structure and mechanical properties of each type.

Types of Plastic Mesh Net

1. Non-Stretching Net

Produced from Low-Density Polyethylene (LDPE) without molecular stretching, this mesh is often used for lightweight applications such as mesh packaging bags for fruits or filter components.

Key Features:

-

Easy to install and retains shape well

-

Moderate load-bearing capacity

-

Less flexible and can tear by hand

Note: Not suitable for high-tension or heavy-duty use.

2. Stretching Net

This type undergoes a heat-stretching process that strengthens the molecular structure. It is available in two variations:

-

Mono-Oriented Netting, Monoaxially Oriented Netting (Single Direction Stretched) – stretched in one direction (vertical or horizontal).

-

Bi-Oriented Netting, Biaxially Oriented Netting (Double Direction Stretched Plastic Mesh) – stretched in both directions for superior multidirectional strength.

Made from Polypropylene (PP) with added UV stabilizers, it provides exceptional outdoor durability and is commonly used as PP Bird Net, PP Chicken Net, or fencing for vegetable plots and animal enclosures.

Key Features:

-

High tensile and impact strength

-

Flexible, non-brittle, and tear-resistant

-

Suitable for both vertical and horizontal installations

Note: Its flexibility may make it slightly more challenging to install in confined spaces compared to rigid meshes.

Custom Manufacturing Options

Siamnet Industry offers custom-made PP Bird Mesh and PP Chicken Mesh according to your exact specifications, including:

-

Mesh size and thickness

-

Width, length, and roll/flat-sheet format

-

Color options and polymer selection

-

Technical adjustments for specific environments

Our team provides technical consultation to ensure every plastic mesh net matches your real-world needs.

Why Choose Siamnet Industry Plastic Mesh?

-

Manufactured from high-grade PP and PE polymers

-

Available in both stretched and non-stretched types for versatile applications

-

UV-protected material for long-lasting outdoor performance

-

Tested for tensile strength and elongation (Warp & Weft) using Universal Testing Machines

-

Strict quality control on mesh size, thickness, and structural uniformity

-

Fully customizable with professional consultation and reliable after-sales support

When people think of high-quality shading nets, the first image that comes to mind is their use in agriculture—filtering sunlight to protect crops—or in construction sites to control dust and debris. However, shading nets can do much more. When adapted into a Fog Collector, they become a remarkable innovation for regions facing water scarcity or frequent morning fog. A fog-harvesting system works on simple physical principles but can convert airborne moisture into clean, usable water — suitable for agriculture, cleaning, or even as an emergency...

A knitted net, also known in some industries as a pump net, is a synthetic material made from high-density polyethylene (HDPE) — an engineering-grade plastic renowned for its toughness, UV resistance, and durability in outdoor environments. Unlike conventional woven or extruded nets, HDPE knitted nets are produced through a knitting process that interlocks filaments in an orderly pattern, similar to textile knitting, but engineered for far greater strength and longevity. Structural Advantages of Knitting The key difference between a knitted net and those made through...

At Siamnet Industry, a shading net manufacturer in Thailand, we use 100% HDPE (High-Density Polyethylene) fibers as the primary raw material for our shade net production. This choice ensures long-term performance in terms of strength, flexibility, and resistance to sunlight and outdoor weather conditions. Key Advantages Observed in Real Use Excellent UV resistance — the material does not easily become brittle or cracked. High elastic recovery — the net stays smooth and taut when stretched or installed. Easy to fold, roll, and reshape without...

What Is Mosquito Screen Net and Why Is It So Widely Used? Mosquito screen net — also known as blue net, insect screen net, insect net, or PE screen net — is made from high-density polyethylene (HDPE) monofilament. It is lightweight yet strong, tear-resistant, transparent, and breathable, while withstanding sunlight, humidity, and outdoor weather for long periods. Thanks to these properties, screen net is used across many industries — from agriculture, animal farming, and aquaculture to household and DIY applications. It’s practical, cost-effective, and easy...

The structure of a rope is the heart of its performance. Whether it’s made through twisting or braiding, the manufacturing process directly affects a rope’s strength, flexibility, and suitability for specific applications. 1. Twine Rope: Durable and Easy to Use Twine rope is one of the most popular rope types, widely used in agriculture, industry, transportation, and general applications. Its main advantages are strength, durability, and ease of use, making it a standard choice across various sectors. Twine ropes are made by twisting synthetic...

- Address: 278 Suk Sawat Rd, Nai Khlong Bang Pla Kot, Phra Samut Chedi District, Samut Prakan 10290

- Telephone: 02-425-9646

- Email: siamnetindustry@gmail.com