High-Quality HDPE Knitted Net — Strong, Flexible, and Versatile

เรื่องcustomercustomer

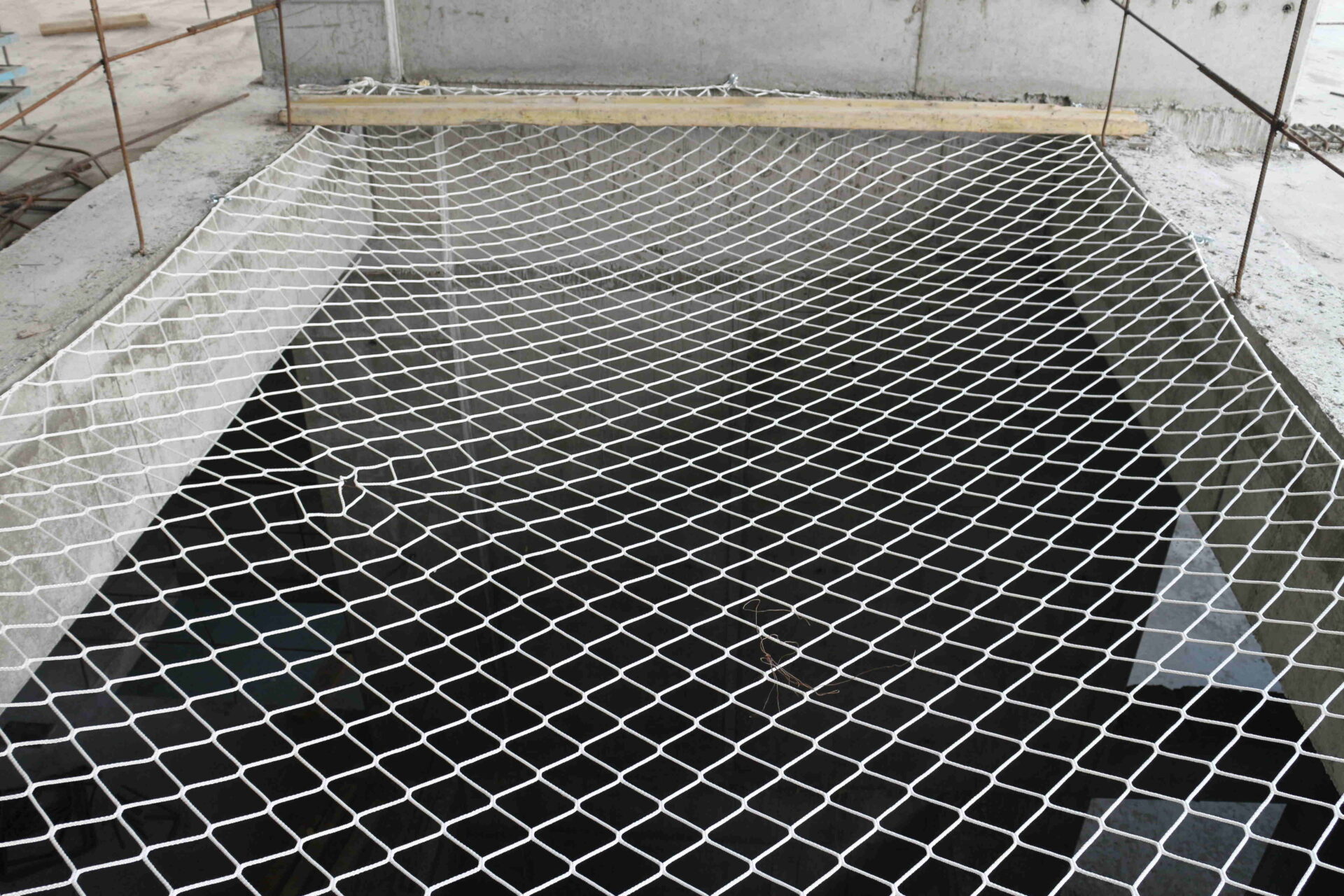

A knitted net, also known in some industries as a pump net, is a synthetic material made from high-density polyethylene (HDPE) — an engineering-grade plastic renowned for its toughness, UV resistance, and durability in outdoor environments. Unlike conventional woven or extruded nets, HDPE knitted nets are produced through a knitting process that interlocks filaments in an orderly pattern, similar to textile knitting, but engineered for far greater strength and longevity.

Structural Advantages of Knitting

The key difference between a knitted net and those made through weaving or extrusion lies in the structure. Knitted fibers are interlinked with inherent flexibility, allowing stress to be distributed evenly in all directions. This reduces the risk of localized tearing and enhances the net’s ability to recover its shape after repeated stretching or impact. As a result, knitted nets are ideal for applications requiring safety, elasticity, and long service life.

Another advantage of knitted nets is their customizable design — users can specify knitting patterns, mesh sizes, and fiber density according to their needs. Examples include:

-

Safety Nets — used in construction sites to prevent falls and enhance worker safety.

-

Cargo Nets — designed for transport and storage, minimizing damage from vibration or movement.

-

Aquaculture Nets — flexible and durable for wet environments, resistant to fish bites and water exposure.

These properties make HDPE knitted nets not only strong and reliable, but also highly adaptable across agricultural, industrial, and general-use applications. With superior performance and cost-effectiveness, knitted nets have become a trusted material standard in various Thai industries.

Reinforced Chain Rachel Structure

Siamnet Industry’s knitted nets utilize a Chain Rachel structure, a specialized knitting technique that enhances strength both vertically and horizontally. This design provides balanced tension across the mesh, maintaining optimal flexibility for use in irregularly shaped areas. Each knitting pattern can be custom-designed — from extra-tight meshes for safety applications to open meshes for ventilation — ensuring suitability for every customer requirement.

Certified Safety Standards

For safety-critical applications such as fall protection nets or construction safety nets, our products are designed and tested according to international safety standards. Each net is produced in compliance with EN 1263-1 and AS/NZS 4389, ensuring sufficient impact resistance and load-bearing capacity to withstand falling objects or personnel without tearing.

Custom Production & Comprehensive Service

At Siamnet Industry, we recognize that every project has unique needs — from mesh pattern, color, and width to specific performance requirements. That’s why we offer a fully integrated, made-to-order production service, including:

-

Sample analysis and material development

-

Custom design based on actual application conditions

-

Production according to client specifications under the supervision of professional engineers

-

Technical consultation to recommend the most practical, cost-effective solution

All processes are conducted under strict quality control, ensuring every net we produce truly meets your goals — whether you need cost optimization or enhanced tensile strength.

Knitted Net vs. Screen Net: Which Is Right for You?

| Feature | Knitted Net | Screen Net |

|---|---|---|

| Structure | Chain-knitted pattern with high flexibility and excellent shape recovery | Plain woven pattern, lightweight and highly transparent |

| Strength | High – withstands strong tension and impact loads, ideal for heavy-duty use | Moderate – suitable for light applications like insect barriers |

| Elasticity | Excellent – multi-directional stress absorption with Chain Rachel knitting | Limited – less shape flexibility due to flat woven construction |

| Specialized Use | Heavy-duty, load bearing, cargo covering, aquaculture | General agricultural or insect-control use |

| Durability | Long-lasting – resistant to harsh sunlight and saline environments | Shorter lifespan – may degrade faster under outdoor exposure |

| Cost | Higher – reflects superior quality and endurance | More economical – suitable for low-stress, general applications |

Choosing the Right Material

-

If you need a tough, UV- and water-resistant net that can withstand tension and continuous use: choose Knitted Net.

-

If you need a lightweight, translucent material for general purposes within a limited budget: Screen Net is the practical choice.

Reference

- “Plastic Nets in Agriculture: A General Review of Types and Applications.” Retrieved on September 23, 2025, from (PDF) Plastic Nets in Agriculture: A General Review of Types and Applications

- “Technical characteristics and requirements of textiles used for building and construction.” Retrieved on September 23, 2025, from Mesh Fabric – an overview | ScienceDirect Topics